I’m enjoying Rework, the entrepreneurial handbook by Jason Fried and David Heinemeier Hanson, founders of 37signals. I was inspired to read it after meeting Mark Rohde, who drew all of the illustrations.

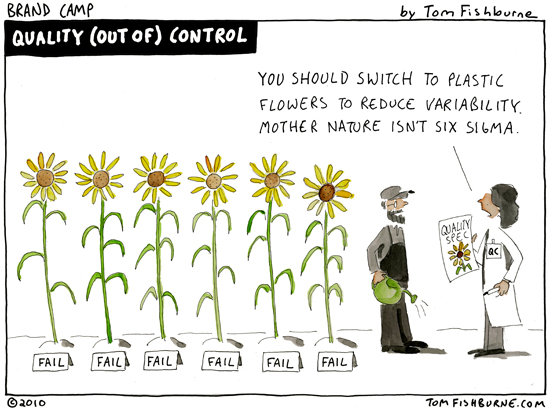

One of the brilliant riffs in the book is titled, “Nobody likes plastic flowers”. Jason and David lobby for the beauty of imperfection and advocate the Japanese principle of wabi-sabi. They illustrate wabi-sabi with a wonderful quote by Leonard Koren:

“Pare down to the essence, but don’t remove the poetry. Keep things clean and unencumbered, but don’t sterilize.”

This flexible philosophy often conflicts with Quality Control, which prizes consistency over “poetry”. The Six Sigma Quality Control movement in particular clamps down on variability.

Strict discipline may be crucial in many forms of product development (otherwise you wind up with the Toyota brake recall). Yet strict quality control standards also sand out the more interesting attributes of product experience. Product development becomes a constant tug-o-war to standardize, not sterilize. How do you write a Quality specification for “poetry”?

When I worked on Häagen-Dazs, we had a lot of internal debates on Quality. We had two US factories, one in California and one in Maryland. The milk came from local farms. East coast milk inherently tastes slightly different from West coast milk because the diet for the cows is different. Yet, our goal was to ensure that West coast ice cream tasted the same as East coast ice cream. Why exactly? Why does Quality Control have to mean absolute consistency? Consumers expect wine brands to taste different from year to year because of crop variability. Why not other products?

Our Mango ice cream created tension because the mango pieces were not consistently sized. Each pint had large pieces and small pieces, as if they were hand-cut, not machine-cut. Consumers liked the variability. Yet, Quality Control wanted to pick one consistent size. It was easier to design a specification that way.

Why can’t mass-produced products accept some variability? Jones Soda features different labels each time you drink them. It is those differences that create drama and interest. Quality is important. But that doesn’t mean that brands should become plastic flowers.

Ted Simon says

Tom,

Once again you’ve captured in one frame what would take most people 1000 words (or more) to communicate. Great observations re the on-going tension between brand experience and the need to “standardize” for operational efficiency’s sake. To paraphrase your own words: it’s sheer poetry.

While Six Sigma is great for standardizing nuts and bolts, much of the brand experience is not about nuts and bolts. There’s a balance that’s appropriate, a line that one shouldn’t cross.

Here’s to brands that reflect nature’s variability and liveliness, something plastic flowers can’t capture.

Cheers,

Ted

@tedlsimon

Cam Beck says

I kinda see your point (and I love the cartoon regardless, as always) but I’m not sure these are the best examples.

For one, mango chunks need a consistent size because they contain water that will leach into the product. Large chunks can break down the consistency of the ice cream over time.

As for variance in the taste of milk — I can see why they would want to keep the flavor consistent for flavors that are supposed to be consistent. IOW, chocolate tastes like chocolate — and you always know what you’re going to get when you taste the chocolate ice cream no matter where in the country you are. This consistency in flavor is an important — if not the most important — brand signature for a food products brand.

However, knowing the limitations might lead you to different solutions. Instead of adding things to the ice creams produced on different coasts to make them taste the same, why not just make sure all chocolate is made on the East coast and vanilla is made on the West coast? Nobody expects chocolate to taste like vanilla, and as long as the flavors are respectively good, the variance in the taste of milk probably would not amount to much difficulty.

Shawne Van Deusen-Jeffries says

Tom,

Cute cartoon but …

Lean and Six Sigma when implemented correctly start with customer requirements especially when used in product development. After collecting and validating the customer requirements then specifications are developed to enable consistent production and thus consistent customer experience.

Many times the problem is that companies focus on internal metrics and forget the customer requirements.

So only plastic flowers and uniform mango chunks if that is what the customer requests.

denise lee yohn says

this is so interesting, tom — especially given that i’m working with a qsr which is struggling with inconsistency — mcdonald’s is on fire these days, and we suspect it’s in part due to their consistency (the logic being that in these times when money is tight, folks would rather go to a place which they know what it will be like even if it’s not great vs. going to a place which is less consistent) — i wonder if people are more tolerant (or perhaps even would welcome more variation) in different economic environments? hmmmm…